Hopkins Baja: Scale Model Body Panel Design

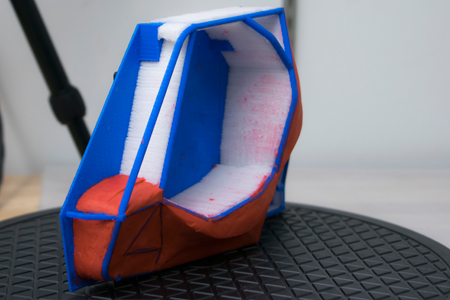

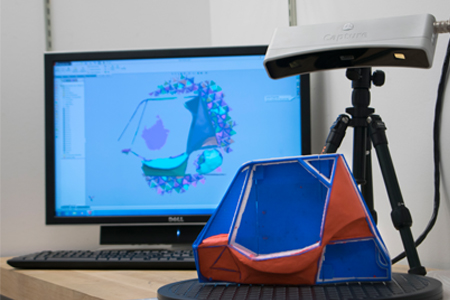

Hopkins Baja SAE, a group of undergraduate engineering students (a car enthusiast) build a car from scratch and take it to competitions with other university teams each year. For the past two years, body panels for the Hopkins Baja SAE team car have been designed in a Computer-Aided-Design (CAD) program. This year, rather than design the panels in CAD, the team decided to design the panels using modeling clay then 3D scan the clay to bring the design into CAD. The first step was 3D printing a scale model of the car frame.

DMC supported the team through our Creative Use of Technology Grant, by purchasing the necessary filament and providing time on our Makerbot Replicator 2X 3D printer so the team could print scale models of their car frame.

Once a scale model of the frame was printed, the team used modeling clay to shape the desired body panels. After the

panels have been shaped, a 3D scanner will be used to bring the design into CAD for manufacturing processes.